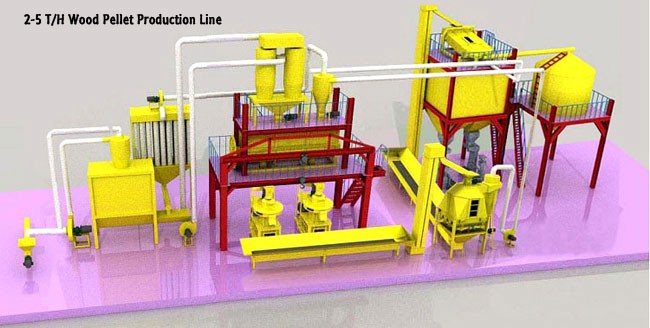

2-5 T/H Wood Pellet Production Line

Technological processes: drying, tempering, mixing, granulating, cooling, screening, packaging and dusting. Required equipments: Wood Pellet Mill, Wood Hammer Mill, Hammer Crusher, Rotary Drum Dryer, Woodchips Dryer, Wood Pellet Cooler, Bucket Elevator, Conveyor Belt.

Capacity: 2-5 t/h

Required equipments: Wood Pellet Mill, Wood Hammer Mill, Hammer Crusher, Rotary Drum Dryer, Woodchips Dryer, Wood Pellet Cooler, Bucket Elevator, Conveyor Belt.

Technological processes: drying, tempering, mixing, granulating, cooling, screening, packaging and dusting.

Advantages on 2-4 t/h Wood Pellet Production Line:

(1) Fote 2-5 t/h wood pellet production line is equipped with 1.5-20 aperture molds, able to adapt to different materials to achieve perfect suppression effect.

(2) Transmission: High-precision gear drive, automatic hydraulic oil circulation system to ensure long life gearbox and stable running.

(3) Components: Mold and pressure rollers are made of alloy steel; independent heat treated; the hardness can be 52 or more to ensure granulating effect and extend equipment life.

Advantages on services:

(1) Service tenet: Quick, decisive, thoughtful and accurate.

(2) Service goal: Use outstanding quality to win customers’ satisfaction!

(3) Service efficiency: As soon as we are notified, we will aid making maintenance if there is a failure, no matter they are under warranty or not.

- Wood Pellet Mill

- Ring Die Wood Pellet Mill

- Rice Hulls Pellet Mill

- Straw Pellet Mill

- Sawdust Pellet Mill

- Cotton Stalks Pellet Mill

- Wood Shavings Pellet Mill

- Biomass Briquette Machine

- Tree Bark Pellet Mill

- Corn Straw Pellet Mill

- Peanut Hull Pellet Mill

- Sunflower Seeds Hull Pellet Mill

- Wood Chipper

- Woodchips Dryer

- Rotary Drum Dryer

- Hammer Crusher

- Bucket Elevator

- Wood Pellet Cooler

- Conveyor Belt

- Screw Conveyor